Session: Imminent supply chain disruptors—What’s your business continuity plan?

Editor's Note

“Can cost and resiliency co-exist?” Michael Schiller, CMRP, executive director (interim) of the Association for Healthcare Resources and Materials Management—a professional membership group of the American Hospital Association—asked this session’s audience on the last day of the OR Business Management Conference. “They can co-exist,” he said, “but resiliency will cost money; in some cases, it does cost a little more to have resiliency.”

Schiller kicked off his presentation by giving attendees a snapshot of the current healthcare financial environment. Some highlights include:

- 2022 was probably one of the worst years from the hospital margin perspective, as over 50% of hospitals were in “negative margin territory”

- margins did improve in December 2023, and hospitals are seeing general improvement overall

- elective procedure volume is starting to trend upward, while average length of stay is going down because there are more beds available compared to pandemic-heavy years—this “reflects an ongoing effort…to develop a clear pathway for discharge and shift toward outpatient revenue,” Schiller said

- outpatient revenue has increased by more than 40% since 2020.

There’s been a lot of activity in the financial market, Schiller said, but it’s “a tale of two cities—some hospitals are doing very well, while others are in some financial distress.” Nearly 40% of 18 hospital proposed deals that were announced recently were driven by financial distress, and “mergers and acquisitions are definitely on the menu for 2024,” he said. There were 65 acquisitions in 2023, which is up from 53 in 2022, and experts are expecting that number to increase.

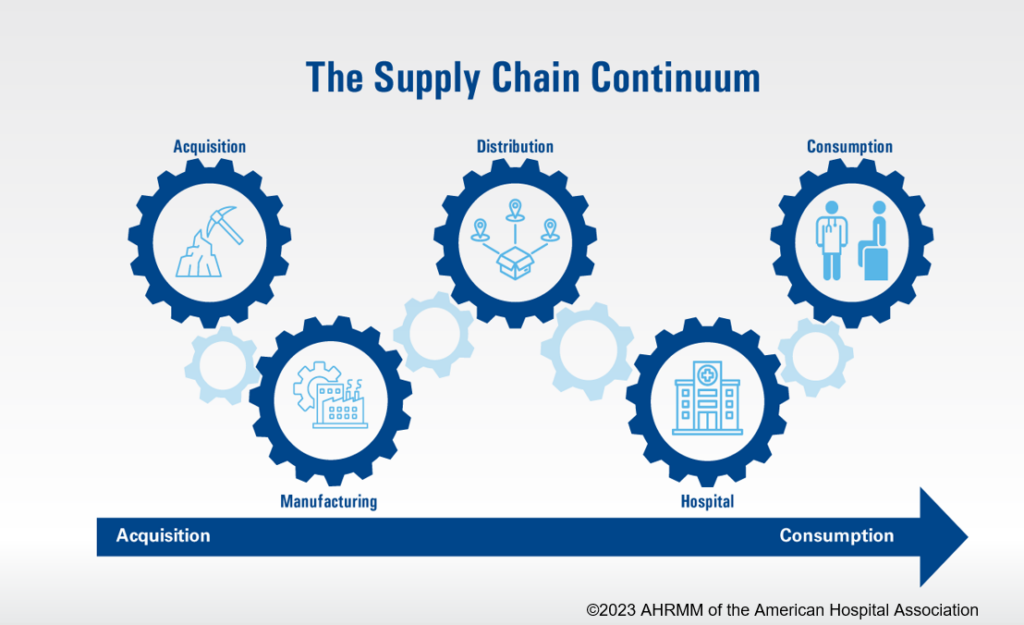

With all this activity, it is a given that the supply chain will show a lot of movement—most of which, history has shown, can be unpredictable. “Will you walk away from this session being reactive, proactive, or transformational?” Schiller challenged, as he urged attendees to pay more attention to supply chain resilience. One big challenge, for instance, is how much supply chain relies on forced human labor. “Eradicating forced labor in the supply chain continuum is a critical priority,” Schiller said. “If you have a product from a manufacturer with confirmed forced labor activity, what will you do with that product?”

Other key terms Schiller presented include circular economy and risk management, which dominated the rest of the session. He urged attendees to think of environmental sustainability as they consider supply chain strategies, including ways to eliminate waste and pollution. One way to do that is to reinvest in environmentally safe resources and choose reusable products when feasible. But no strategy is safe without collaboration, and no resilience plan works without a plan to mitigate risk. “Risk management is an area we need to be working with much more closely as we look to bring in new suppliers to fortify our supply chain,” Schiller said.

Read More >>

Free Daily News

Free Daily News